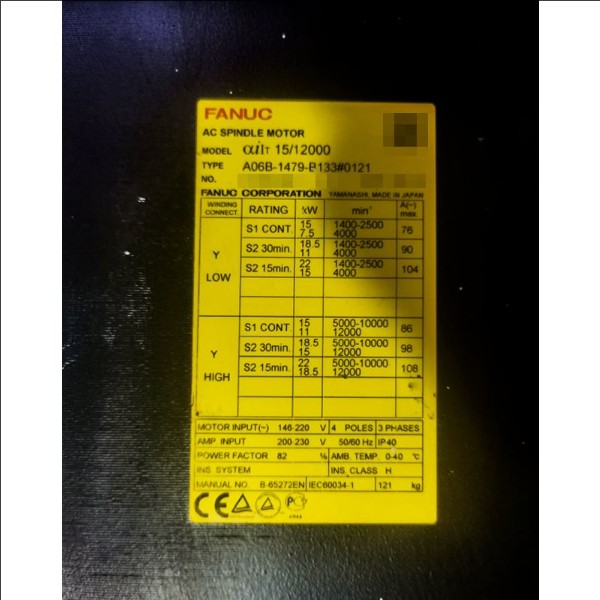

FANUC A06B-1479-B133 A06B-1479-B135

- Category: FANUC Motor

- Brand: FANUC

- Country of origin: Japan

- Warranty: 1 year for new, 3 months for used

- Type: FANUC Spindle Motor

- Lead time: 1-2days

- Series: FANUC AiIT 15/12000

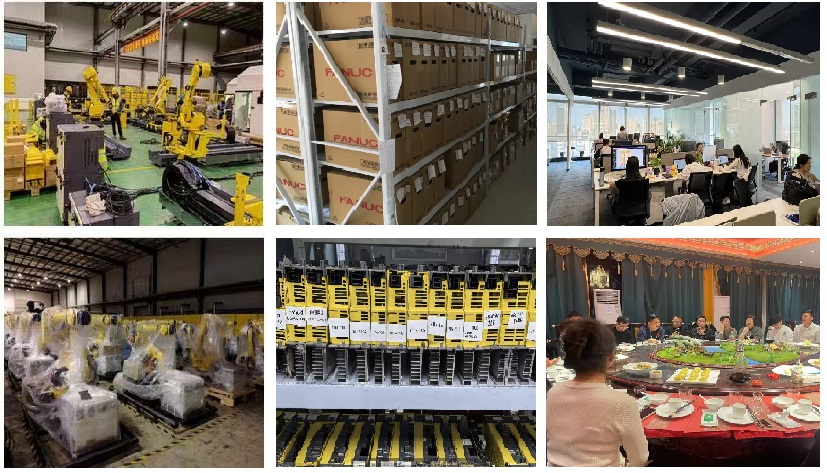

Why Choose Us?

1. There is a large number of stocks, can be delivered within 1-2 days.

2. With a experienced technical support team, all the parts are 100% tested ok before sold out.

3. 90 Days guarantee for Used parts, 365 Days guarantee for New parts.

4. Free technical consultation.

5. Almost all payment and shipping methods are acceptable.

Package&Delivery

We will fill thick foam at the bottom of the box and wraps around the inside parts to make sure the products will be damaged in the transit.

The heavy products will be packaged in the customized wooden box.

The packages will be sent by DHL, UPS, FedEx,EMS etc. If you have any special needs, please let me know.

FAQ

Q: What’s your main business?

We sell and repair Fanuc, Mitsubishi, and Siemens products and provide other CNC spare parts to the worldwide.

Q: Where is your company?

Our company is located in Hangzhou City, where Alibaba is headquartered.

Q: Do you have the test bench? What’s the delivery time?

We have the completed testing benches, and all parts are tested well before dispatch. Most of the parts are in stock, so the delivery time is usually 1-2 days.

Q: What's the guarantee of your parts?

The guarantee period for used parts is 3 months, 1 year for new. If you receive unworkable parts , you can return it back to us within 7 days.

Q: How about the packing?

We usually use foam paper to fill all the areas inside the box to protect the parts. If the parts are too heavy, we will customize wooden box for packing.

Q: What’s the payment method?And shipping method?

T/T, PayPal, Credit Card.

UPS, DHL, FedEx, EMS are available.

INQUIRY

CATEGORIES

CONTACT US

Name: Zoe Zhang

Mobile:+86 17357958505

Whatsapp:+86 17357958505

Email:sales01@jerehcnc.com sales02@jerehcnc.com

Add:Room F1143,11th Floor,Building 2,368 Yearning Street,Wuchang Street,Hangzhou City,Zhejiang Province,China